If your display shows a code and the cycle will not run, start here. This guide covers the most common Maytag washer error codes across top load and front load models, including Maytag Bravos, Bravos XL, Centennial, and MHW front load series. Because Maytag shares the Whirlpool control platform in many models, several Whirlpool-style codes and reset steps also apply.

Want a pro to handle it? Book a washer repair service, or contact ARS.

Quick reset and diagnostics

- Soft reset: Power the washer off, wait 1 minute, power on, choose Normal, press Start. On many models, holding Start or Pause for 3 to 5 seconds clears temporary faults.

- Hard reset: Unplug for 2 to 3 minutes, then plug back in. This clears some “stuck” Maytag washer fault codes.

- Diagnostic mode: Many Maytag units support service tests that show stored Maytag washer problem codes. Entry varies by model; see the official links below for your exact sequence.

Top load vs front load code formats

- Top load Maytag washer error codes often use plain text like drn, Ofb, LdU, or LdL; newer platforms also show F# E#.

- Front load Maytag washer error codes commonly use the F# E# format (for example F9 E1, F8 E1, F5 E2, F0 E2).

- These steps also help with searches like Maytag Bravos error codes, Maytag Bravos XL error codes, Maytag Centennial washer error codes, and general Maytag washer troubleshooting codes.

Error codes and fixes (quick reference)

| Code | Meaning | Common causes | DIY checks and fixes | Notes |

|---|---|---|---|---|

| F9 E1 or drn | Long drain | Kinked/clogged drain hose, blocked pump filter, low standpipe height, oversuds | Clear hose and pump filter. Verify standpipe 36–96 in above floor; floor drain needs a 28 in siphon break. Run Rinse & Spin to clear suds. | Often searched as “Maytag washer code F9 E1” or “E1 F9 Maytag washer”. |

| LF, Lo FL, or F8 E1 | Long fill / low flow | Closed valves, kinked inlet hoses, clogged screens, siphoning | Open hot and cold valves, straighten hoses, clean inlet screens, confirm standpipe height, ensure both hot and cold supply. | Sometimes shows as “Maytag washer F8 E1 code”. |

| HC | Hot/Cold reversed | Hoses swapped at rear | Swap hoses, run a short cycle to confirm temps. | |

| F8 E3 | Overflow / water level high | Oversuds, siphoning, pressure hose issue | Power off, close valves, reduce detergent, check pressure hose/tub air dome, confirm drain height. | |

| Sd or F0 E2 | Suds detected | Non-HE or too much detergent, mixing products | Run Rinse & Spin with no detergent. Use HE only and measure correctly. | Seen on front and top load units. |

| Ofb, uL/UL, or F0 E5 | Off balance | Mixed heavy/light items, bulky load, out-of-level feet | Redistribute, remove one heavy item, level feet and tighten lock nuts, reduce spin speed for bulky items. | Bravos/Bravos XL often display Ofb/uL. |

| F0 E3 | Overload detected | Too much laundry, dense textiles | Remove items and retry; avoid overpacking the basket. | |

| F5 E2 / F5 E3 | Door/lid will not lock or unlock | Obstruction, latch not fully seating, wiring | Clear items at the door/lid, power cycle, try again. Persistent codes may require lock service. | Front loads usually show F5 Ex; top loads may show LdL/LdU. |

| LdL / LdU / Lid | Lid not locked / won’t unlock / lid open | Heavy item pressing lid, obstruction at latch, lid left open | Remove heavy items, close fully, wait for motor to stop, retry. Close lid within 10 min to avoid cycle reset. | Common on Centennial and Bravos. |

| F7 E1 | Basket speed sensor fault | Overload, binding basket, speed sensor issue | Lighten load, spin basket by hand to check for binding, power cycle. If it returns, sensor/harness may need service. | Front loads and some top loads. |

| F7 E5 | Shift actuator fault | Top load shifter stuck or wiring issue | Power reset, listen for shifting. If persistent, shifter or harness service is likely. | Top load VMW platform. |

| F7 E7 | Motor cannot reach target speed | Overload, drag, capacitor/drive issue | Reduce load, check for items stuck between tub/basket, retry. Service if it repeats. | |

| F3 E1 | Water level system error | Pressure hose kink/leak, sensor fault | Inspect and reseat pressure hose; if code returns, service is recommended. | |

| F3 E2 | Inlet water temperature sensor | Temp sensor reading out of range | Verify supply temps, correct HC hose orientation; service if persistent. | |

| F2 E1 | Stuck or shorted keypad | Key pressed too long, moisture in console | Power off to dry, avoid pressing multiple keys. If repeated, UI may need service. | |

| F6 E2 / F6 E3 | UI to main control communication | Loose harness, control fault | Power cycle several minutes. If it returns, professional diagnosis is required. | |

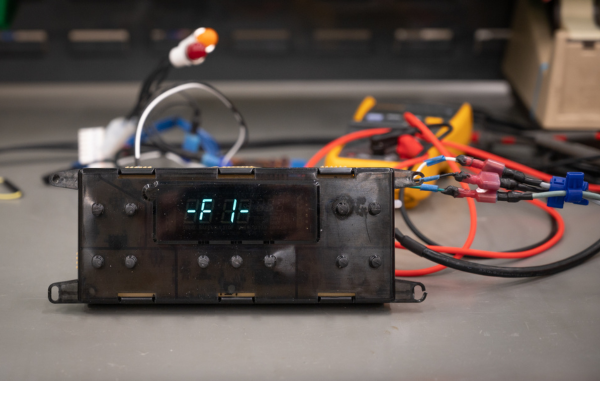

| F1 E1 | Main control fault | Control board internal error | Power reset. If the code reappears immediately, service is necessary. | |

| dET | Detergent cartridge not detected | Load & Go not seated | Reinsert cartridge or use single-dose mode per manual. | Front load MHW with Load & Go. |

| rL | Items detected in Clean Washer cycle | Clothes left inside | Remove items and restart Clean Washer. | |

| E01 F09 (legacy) | Long drain on older front loads | Blocked pump, hose, or standpipe issues | Same checks as F9 E1; also inspect coin trap on applicable models. | Common on older Whirlpool/Maytag front loads. |

Drain and fill codes

F9 E1 or “drn” , Long drain

- Meaning: Tub did not drain within the expected time.

- Likely causes: Kinked or crushed drain hose, blocked standpipe, clogged pump filter/impeller, low hose height causing siphon, oversuds.

- DIY checks: Straighten/replace hose, clear standpipe, clean pump filter or coin trap, confirm standpipe height 36–96 in (floor drains need a 28 in siphon break), run Rinse & Spin to clear suds.

LF, Lo FL, or F8 E1 , Long fill / low flow

- Meaning: Washer took too long to fill.

- Likely causes: Closed valves, kinked inlet hoses, clogged screens, low supply pressure, siphoning from a low drain.

- DIY checks: Fully open hot and cold valves, straighten hoses, clean inlet screens, confirm standpipe height, verify hot and cold supply.

HC , Hot and cold reversed

- Meaning: Hoses swapped or unexpected temperature reading.

- Fix: Swap the inlet hoses at the back of the washer and run a short cycle to confirm.

F8 E3 , Overflow

- Meaning: Water level continued to rise when it should not.

- DIY: Power off, reduce detergent dosage, check pressure hose and tub air dome for pinches/leaks, correct standpipe height, restart.

Door and lid lock codes

F5 E2 or F5 E3 , Door/lid will not lock or unlock

- Meaning: Control did not sense a proper lock/unlock state.

- DIY checks: Remove laundry pinched in the door, clean latch strike area, power cycle and retry. Persistent codes point to a failing latch or harness.

LdL , Lid not locked

- Fix: Remove items resting on the lid, press down to fully close, restart.

LdU , Lid will not unlock

- Fix: Pause and wait for motor to stop; remove heavy items pressing on the lid; try again. A stuck lock may require service.

Lid , Lid open too long

- Meaning: Lid stayed open for ~10 minutes. Close lid and press Start to resume.

Load balance and suds codes

Ofb or uL/UL or F0 E5 , Off balance

- Meaning: Load is unbalanced; washer may attempt auto-correction.

- DIY: When safe, redistribute items, remove one heavy article, level and lock feet, choose lower spin for bulky items.

Sd or F0 E2 , Suds detected / oversuds

- Meaning: Excess suds preventing proper spin or drain.

- DIY: Rinse & Spin with no detergent; use HE only and measure accurately; avoid mixing liquid softener into the detergent drawer.

Motor, speed, and actuator codes

F7 E1 , Basket speed sensor fault

- Meaning: Control did not detect expected rotation.

- DIY checks: Remove heavy/jammed items, spin basket by hand to check for binding, power cycle and retry. Repeats indicate sensor, motor, or harness issues.

F7 E5 , Shift actuator fault

- Likely causes: Top load shifter stuck or wiring issue.

- DIY: Power reset and listen for shifting. If persistent, shifter or harness likely needs service.

F7 E7 , Motor unable to reach target speed

- Likely causes: Overload, drag, failed capacitor (some top loads), drive issue.

- DIY: Reduce load size, check for items between tub and basket, retry.

Water level and inlet temperature codes

F3 E1 , Water level system error

- Meaning: Pressure sensor signal invalid.

- DIY: Power off, inspect small pressure hose from tub to control for kinks, pinholes, or disconnection; if it returns, service is recommended.

F3 E2 , Inlet water temperature sensor

- DIY: Verify hot and cold supply and temperature. If unexpected after HC checks, the temperature sensor or control may require service.

Control and communication codes

F1 E1 , Main control fault

- Fix: Power cycle. If the code returns immediately, control board diagnosis is required.

F6 E2 / F6 E3 , UI to main control communication

- DIY: Power off several minutes, confirm console responds and no buttons are stuck. If persistent, service is needed.

F2 E1 , Stuck or shorted keypad

- DIY: Power off to let the console dry if moist; avoid long multi-key presses; retry.

Detergent and cleaning messages

dET , Detergent cartridge not detected

- Meaning: On Load & Go models, the cartridge is missing or not engaged.

- DIY: Reinsert cartridge firmly or switch to single-dose mode per the manual.

rL , Items detected during Clean Washer cycle

- Fix: Remove laundry and restart the Clean Washer cycle.

Legacy code

E01 F09 , Long drain (older front loads)

- DIY: Same checks as F9 E1; also inspect and clean the coin trap if your model has one.

Standpipe and drain height cheat sheet

- Standpipe or laundry tub: 36–96 inches above the floor

- Floor drain: siphon break at approximately 28 inches

- Incorrect heights cause siphoning, long fill, and long drain faults.

Helpful official resources

Summary

This expanded list covers the most searched Maytag washer error codes and fixes: F9 E1 long drain, F8 E1/LF long fill, HC hose reversal, F8 E3 overflow, Sd/F0 E2 suds, Ofb/uL/F0 E5 off balance, F0 E3 overload, F5 E2/F5 E3 door/lid, F7 E1/E5/E7 motor and speed, F3 E1/E2 level/temperature, F2 E1 keypad, F6 E2/E3 communication, F1 E1 control, plus dET and rL. If the same code returns after basic checks and a reset, schedule washer repair or contact ARS.

ARS Appliance Repair Service has been trusted across Toronto, Ottawa, and Southern Ontario for over a decade. Our licensed, manufacturer-authorized technicians specialize in repairing all major household and commercial appliances with genuine parts and warranty-backed service. From refrigerators and washers to ovens, dishwashers, and more, we restore appliances quickly, professionally, and correctly the first time, earning the confidence of homeowners and businesses throughout the region.