If your dryer runs but there’s no heat, or it takes forever to dry, use this field-tested guide to find and fix the problem fast. Covers electric and gas dryers: fast checks, airflow/venting, thermal fuses, heating elements, igniters, gas coils, thermostats/thermistors, moisture sensors, controls, and more.

Most “no heat” complaints start with airflow or power/gas supply. Start with the basics below.

Most “no heat” complaints start with airflow or power/gas supply. Start with the basics below.If your dryer tumbles but won’t heat, or a load needs two or three cycles, you’re dealing with a heating or airflow fault. Use this step-by-step guide to diagnose and fix both electric dryers (240V element) and gas dryers (igniter + gas valve coils). We’ll also show when to clean the vent, what to test with a multimeter, and when it’s time to call a pro in the GTA.

Safety first

- Unplug electric dryers before any disassembly. For gas dryers, unplug and close the gas shut-off before accessing parts.

- Restore power/gas only with all panels reinstalled. Avoid live testing unless you’re qualified.

- Let hot parts cool. Wear gloves/eye protection. Keep water away from control boards and igniters.

Quick wins (2–5 minutes)

- Clean the lint screen & housing: If fabric softener left a film, wash the screen with dish soap, rinse, dry, and wipe the housing.

- Check outdoor airflow: While heating, the exterior hood flap should open fully with strong, steady exhaust. Weak/pulsing flow = blocked vent. Disconnect the duct at the dryer back and retry, if heat returns, clean the full vent run.

- Electric only: Reset the double 240V breaker (OFF → ON). A motor can spin on 120V with no heat if one leg is tripped.

- Gas only: Confirm the gas valve is fully ON. Through the burner peep hole, you should see glow → click → steady blue flame.

- Cycle sanity check: Make sure you’re not on Air Fluff/No Heat. Run a short Timed Dry test. If Timed works but Auto ends early, clean the moisture sensor bars with isopropyl alcohol.

Symptoms → likely causes → first checks

| Symptom | Likely cause(s) | What to check first |

|---|---|---|

| Drum turns, no heat (electric) | Half-tripped breaker (240V), open thermal fuse, failed element, open hi-limit/thermistor | Reset breaker → test fuse/element continuity → inspect venting |

| Heats, then stops mid-cycle | Overheat from restricted vent, weak gas coils (gas), cycling thermostat trip | Outdoor airflow → brief run with vent disconnected → gas coils if flame drops out |

| Gas: igniter glows, no flame | Weak gas valve coils, closed valve, flame sensor/wiring | Open gas → replace coil kit → inspect sensor wiring |

| Gas: no glow/no click | Open igniter, blown fuse, bad door switch, control/relay issue | Igniter continuity → thermal fuse → door switch |

| Auto cycle ends too soon | Dirty moisture sensor bars, tiny loads, Eco settings | Clean bars with alcohol → compare on Timed Dry |

| Heats but takes forever | Clogged vent, crushed/kinked duct, coated lint screen, overloaded drum | Clean/shorten vent run; wash screen; lighten load |

Step-by-step: fix a dryer that won’t heat

1) Airflow & venting (the #1 cause of “no heat” and long dry times)

Restricted venting makes dryers overheat and shut down the heat, blow thermal fuses, or just crawl through cycles. Use 4″ rigid or semi-rigid metal duct only (no plastic/foil). Keep runs short with gentle elbows. Clean the hood, duct, and lint screen channel.

- Exterior hood test: Strong airflow? If weak/pulsing, disconnect the duct at the dryer and retest heat.

- Vent path: Replace crushed foil/plastic with short, straight semi-rigid or rigid 4″ metal. Minimize equivalent length; use wide-radius elbows.

- Clean the run: Long runs or multiple elbows often need a full clean. Lint clogs cause slow dry and trip safety devices. See dryer exhaust hose & lint trap cleaning.

2) Power or gas supply

- Electric: Verify 240V present (motor can run on 120V). Reset the double-pole breaker; inspect cord/outlet for heat damage or a dropped leg.

- Gas: Valve must be fully open; verify supply by checking another gas appliance.

3) Electric dryer heating circuit

Unplug before testing. Use a multimeter for continuity/ohms.

- Thermal fuse: Usually on the blower housing. If open, the dryer won’t heat. Replace the fuse and fix the root cause (vent restriction). Need a walkthrough? See how to replace thermal fuse 3392519.

- Heating element: Look for broken coils or short to chassis. Continuity between terminals; no continuity from coil to ground.

- Hi-limit thermostat / cycling thermostat / thermistor: Test per your model specs. Replace any open/out-of-range parts.

- Terminal block & wiring: Burnt spades/loose conductors can drop a leg. Repair harness and tighten connections.

4) Gas dryer burner system

Shut off gas and power for disassembly. Restore gas only when testing with panels in place.

- Igniter glows but no flame: Classic gas valve coil failure. Replace both coils together; verify flame sensor wiring.

- No glow at all: Test igniter continuity; inspect thermal fuse and door switch. Replace a cracked/open igniter.

- Flame lights, then quits after a few minutes: Weak coils or vent restriction causing hi-limit trips. Verify airflow first, then replace coils if needed.

5) Moisture sensor & cycles

- Clean the two metal sensor bars (front bulkhead) with isopropyl alcohol, dryer-sheet residue causes false “dry.”

- Compare Timed Dry vs Auto to isolate sensor-related shutoff.

6) Controls and relays

If relays click but the heater never energizes (and all components test OK), the control board or heater relay may be faulty. Consider professional dryer repair.

Electric vs. gas: quick differences

| Type | Heats by | Common “no heat” causes |

|---|---|---|

| Electric | 240V heating element | Half power (tripped leg), open thermal fuse, failed element, open hi-limit/thermistor, restricted vent |

| Gas | Igniter + gas valve + coils | Gas off, weak coils, open igniter, flame sensor/wiring issues, restricted vent overheating |

Heat-pump / condensing dryers (ventless)

- Clean the heat exchanger/condenser and screens monthly; empty the water tank (if not plumbed).

- Clogged exchangers mimic “no heat” with very long dry times; follow your model’s maintenance steps.

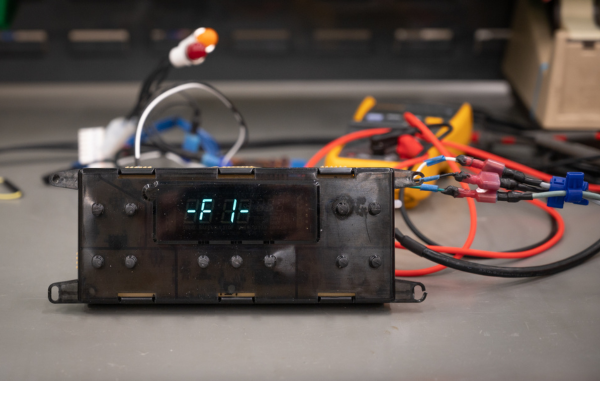

Brand hints & service codes

- Whirlpool/Maytag: AF or “Check Vent” = airflow restriction. Troubleshooting a specific brand? See why a Maytag dryer may not dry.

- LG: d80 / d90 / d95 = 80–95% vent blockage detected.

- Samsung: HE (heating error), HC, tS/t0 (thermistor). Full list here: Samsung dryer error codes.

- Repeated thermal-fuse blows almost always point to venting or a cycling thermostat problem.

60-second moisture sensor cleaning

Parts, symptoms, DIY difficulty & typical time

| Part | Common symptom | DIY level | Typical time |

|---|---|---|---|

| Lint/vent system | Long dry time, hot cabinet, AF/d80–d95 codes | Easy–Medium | 30–90 min (full run) |

| Thermal fuse | No heat at all | Easy | 20–40 min |

| Heating element (electric) | No heat; breaker OK | Medium | 45–90 min |

| Gas valve coils (gas) | Glows but no flame; short cycling | Medium | 30–60 min |

| Igniter (gas) | No glow | Medium | 30–60 min |

| Moisture sensor clean | Auto cycle ends early | Easy | 5 min |

Multimeter mini-guide (for confident DIYers)

Safety: Unplug dryer and turn off gas. If you’re not comfortable testing, skip to a pro.

- Thermal fuse / thermostats: Continuity ≈ 0 Ω at room temp. If open, replace.

- Heating element: Typically ~8–50 Ω between terminals; ∞ to chassis. Open/grounded = replace.

- Igniter (gas): Often ~50–400 Ω. Open = failed igniter.

- Flame sensor: Closed at room temp; opens when hot. Stuck open = replace.

Repair vs. replace — a quick rubric

- Repair if the dryer is <8–10 years, cabinet is sound, and the issue is venting, fuse, coils, igniter, thermostat, or element.

- Consider replacement for severe drum/bulkhead damage, repeated control failures, or if repair cost > ~50% of a quality replacement.

Maintenance to prevent “no-heat” callbacks

- Every load: Clean the lint screen; don’t overload; keep softener off the sensor bars.

- Monthly: Wash the lint screen with dish soap to remove invisible fabric-softener film.

- Annually: Clean the entire vent run (more often for long runs, condo bends, pets). Build a routine with our dryer maintenance checklist.

Helpful resources

Dryer “no heat” FAQs

Why is my dryer running but not heating?

Top causes: tripped 240V breaker (electric), clogged vent, blown thermal fuse, failed heating element/igniter, or bad gas valve coils. Start with airflow, then test parts.

Gas dryer not heating but the igniter glows?

Usually weak gas valve coils or a faulty flame sensor. Airflow restrictions can cause short-cycling too, clear the vent and replace the faulty part.

Dryer heats but takes too long to dry, what now?

Almost always venting. Clean the full run, confirm the outdoor hood opens fully, and wash the lint screen to remove fabric-softener film. Use 4″ rigid/semi-rigid metal duct.

Is it safe to run the dryer without a vent?

No. Venting indoors adds moisture and raises fire risk. Always vent outdoors with 4″ metal duct.

How often should I clean the dryer vent?

At least annually, or sooner if you see airflow warnings (AF/d80–d95) or notice longer dry times.

How do I know if the thermal fuse is blown?

With power unplugged, remove one lead and check continuity across the fuse. “Open” = blown. Always fix the airflow restriction that caused it or it will blow again.

Is it safe to use foil or plastic flex duct?

No. Use a short, straight run of semi-rigid metal duct with proper clamps. Avoid long, crushed, or accordion-style plastic/foil ducts.

Clothes are warm but still damp, what gives?

Classic poor airflow or oversized load. Clean the vent and screen housing, shorten the duct run, and avoid overloading the drum.

Service areas

We repair and maintain dryers across Toronto and the GTA, including Mississauga, Brampton, Vaughan, Markham, Richmond Hill, Scarborough, North York, Etobicoke, Oakville, Burlington, Milton, Pickering, Ajax, Whitby, Oshawa, Aurora, Newmarket, Barrie, and Hamilton.

Need help now? Book dryer repair service or call 1-866-415-3937.

Dryer still not heating? We can help today.